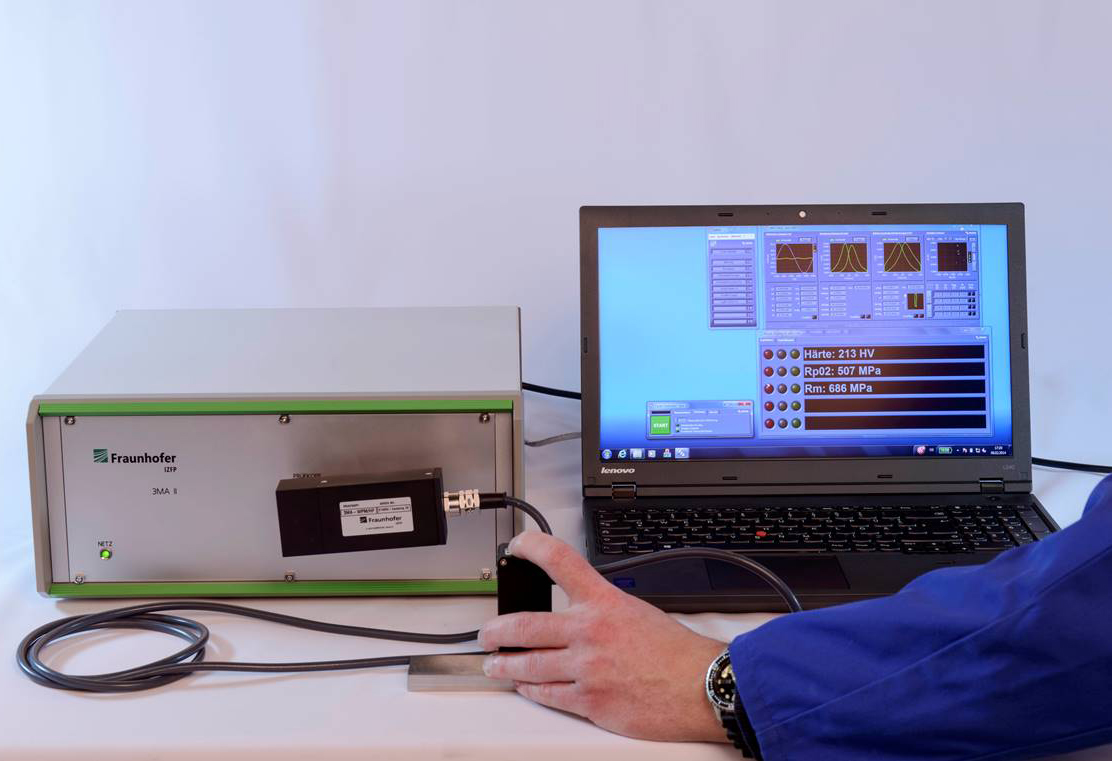

3MA-SOM Steel Online-Monitoring System is the comprehensive online non-destructive testing solution accounting for all parameters of interest. For example, Yield Strength, Tensile Strength, Alongtion, Hardness, instead of measured in the laboratory at randomly taken samples.

Inquiry Online Sales Manager: Mr Li

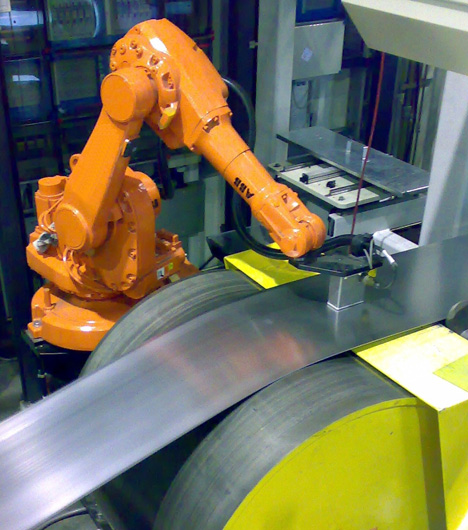

Sales Manager: Mr LiMachine-Material-Interaction: 3MA system integrated in the production line in order to monitor mechanical-technological material properties of steel strip during manufacturing

Since the 1920s, steel has been the material of choice for automakers worldwide. Today, steel makes up around 65 % of an average automobile’s weight and is the backbone of the entire vehicle. On average, that is 900 kg of steel used per vehicle.

Strip steels are used in the automotive industry for car body constructions in order to reduce vehicle weight (and therefore the CO2 equivalents) while maintaining or even improving safety and reliability of the construction, in short, for Stronger, Lighter and Safer Cars. However, the beneficial properties of advanced high-strength steel are much more sensitive to process variations than those of regular steel, raising the need for improved process monitoring and quality control. The same applies to other advanced steel qualities. So far, there is no comprehensive online testing solution accounting for all parameters of interest. For example, Yield Strength, Tensile Strength, Alongtion, Hardness, are still measured in the laboratory at randomly taken samples.Usually, the mechanical properties of strip steel have to be assured by taking samples from the beginning and end of the strip rolled to a coil. These samples undergo time-consuming tensile tests, after which the coil is released. The time delay between sample collection and testing can reach up to several hours. During this time the finished coil can’t be shipped and has to be temporarily stored in the coil yard. A quick detection and reaction on deviations in the production process is not possible. For that reason, steel industry has a vital interest in inline testing mechanical properties of strip steel. 3MA is suitable for various kinds of steel used in all industries (automotive, aerospace, railway, metal production and processing, energy, ...)

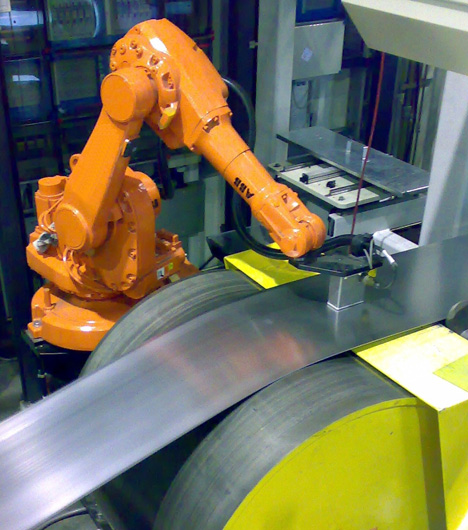

The 3MA probe is fitted to a robot or into an electropneumatic manipulator, as shown in figures above. Usually, 3MA probe application is contact-free with a nominal lift-off from the strip between 1 and 8 mm. Typical applications of 3MA nondestructive testing methods along the value-added chain:For example, the plot of a continuous measurement of Yield strength Rp0.2 in a 2.5 km long strip is shown in figure above.

For more details, please contact LAB GAGES directly.

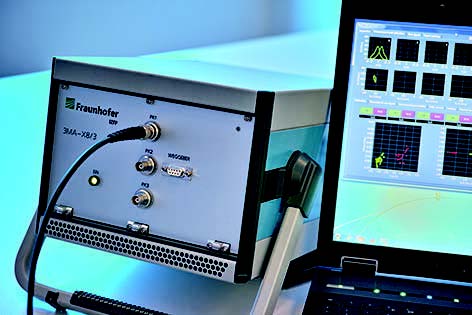

3MA THD Multi-Function Measuring Instrument

3MA THD Multi-Function Measuring Instrument 3MA-X8 System for Fast Materials Characterization

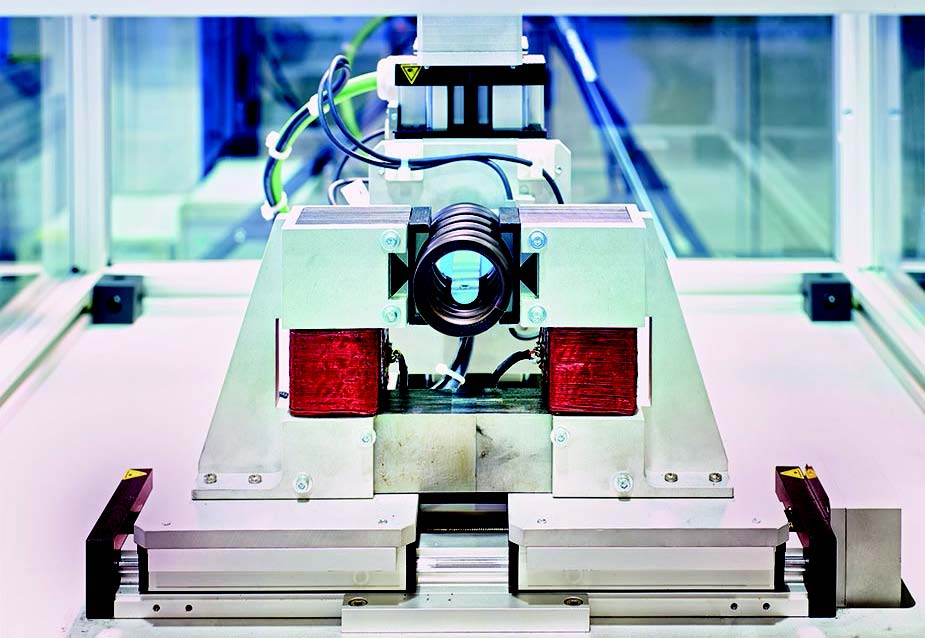

3MA-X8 System for Fast Materials Characterization Hardness & Residual Stress Depth Profiles NDE Scanner

Hardness & Residual Stress Depth Profiles NDE Scanner 3MA Inspection of Press Hardening Parts

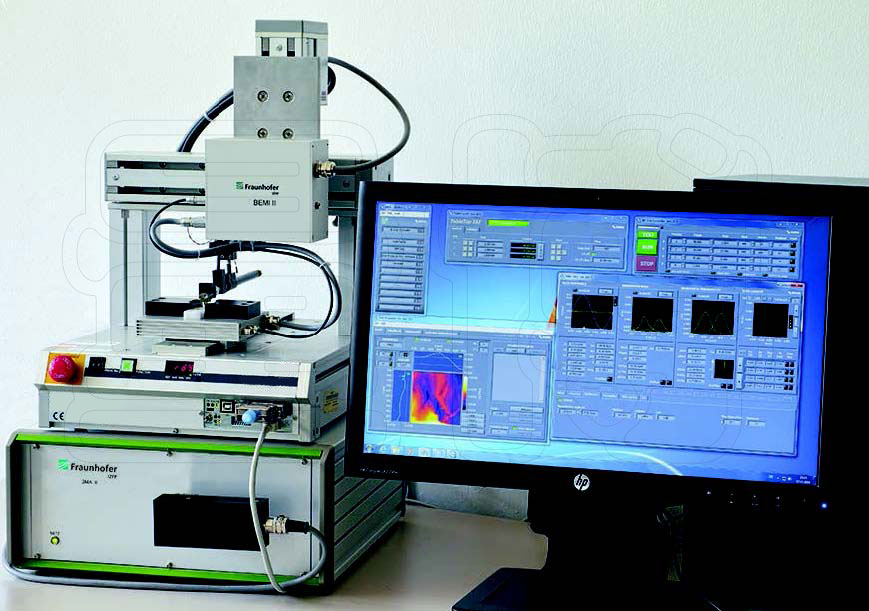

3MA Inspection of Press Hardening Parts Barkhausen Noise and Eddy Current Microscope BEMI

Barkhausen Noise and Eddy Current Microscope BEMI Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel

Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel 3MA-SOM steel online monitoring system

3MA-SOM steel online monitoring system 3D SmartInspect-Intelligence in Inspection and Quality Control

3D SmartInspect-Intelligence in Inspection and Quality Control

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號

滬ICP備12021537號-1

©2012-2024 LAB GAGES

滬ICP備12021537號-1

©2012-2024 LAB GAGES