Steel manufacturing and steel processing industries require NDT methods for quality control. Hardness, case depth, strength, and residual stresses are major quality features in demand. The 3MA-X8 inspection system is especially zeroing in on high measurement velocity and variable sensor shaping, allowing to deal with multiple measuring positions or to accelerate area scans.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr LiSteel manufacturing and steel processing industries require nondestructive testing methods for quality control. For this purpose hardness, case depth, strength, and residual stresses are major quality features in demand. Ferromagnetic steels and cast iron show a distinct correlation between magnetic behavior und mechanic-technological materials characteristics. Hard-magnetic materials – viz. materials that are difficult to magnetize or to degauss – mostly show mechanical hard and brittle characteristics, while soft-magnetic materials like pure iron use to be mechanical ductile. Equally, residual and load stresses exert a comparable influence on magnetic processes. Hence, in many cases these nondestructively gaugeable magnetic properties can be used to analyze mechanical material behavior and stress states.

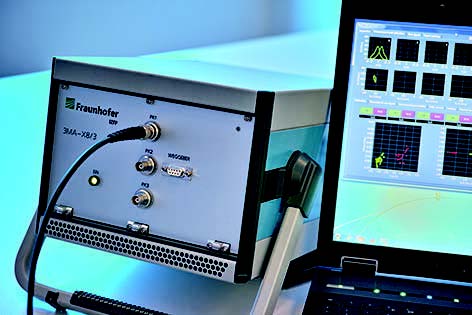

Case depth determination by 3MA-X8

Case depth determination by 3MA-X8

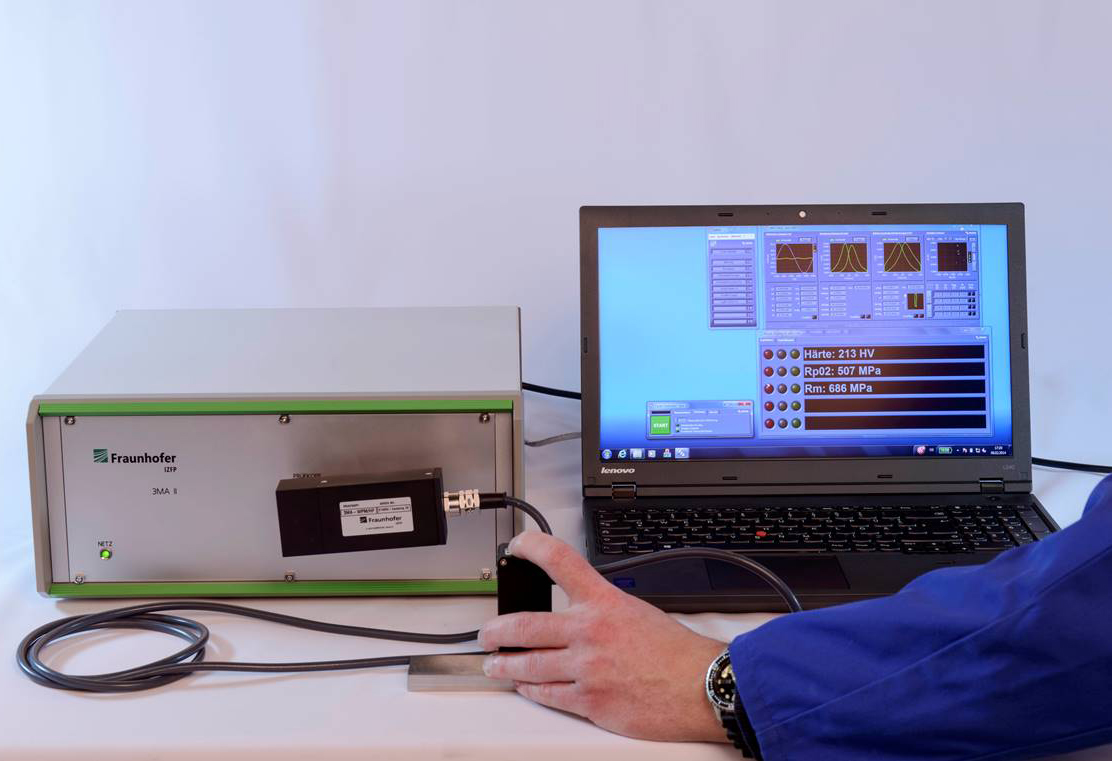

3MA is an integrated NDT Technology, which is the accronym for “Micromagnetic Multiparameter, Microstructure and stress Analysis“. Within fractions of a second, Fraunhofer IZFP‘s 3MA inspection systems measure how hard- or soft-magnetic a material is. Moreover, a multitude of different magnetic parameters are determined which are correlated to different material properties or residual and load stresses. By a predefined set of calibration samples the 3MA method identifies the correlation between magnetically measured parameters and the target values as required by the customer (e.g. hardness, case depth, tensile strength, yield strength, residual stresses). This is realized by mathematical-statistical tools like pattern recognition and regression analysis. Finally, the calibration can be used to inspect calibrated types of assemblies, components or semifinishes.

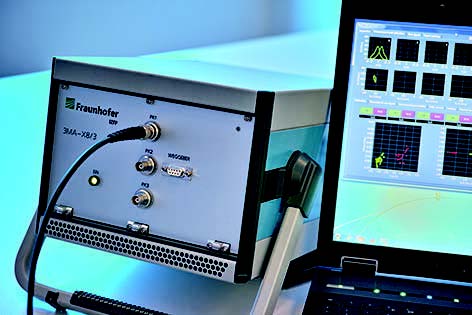

The 3MA-X8 inspection system is a 3MA variation especially zeroing in on easy calibration, high measurement velocity and variable sensor shaping. Additionally, the parallel operation of up to 8 sensors in one device is possible, thus allowing to deal with multiple measuring positions at same time or to accelerate area scans.

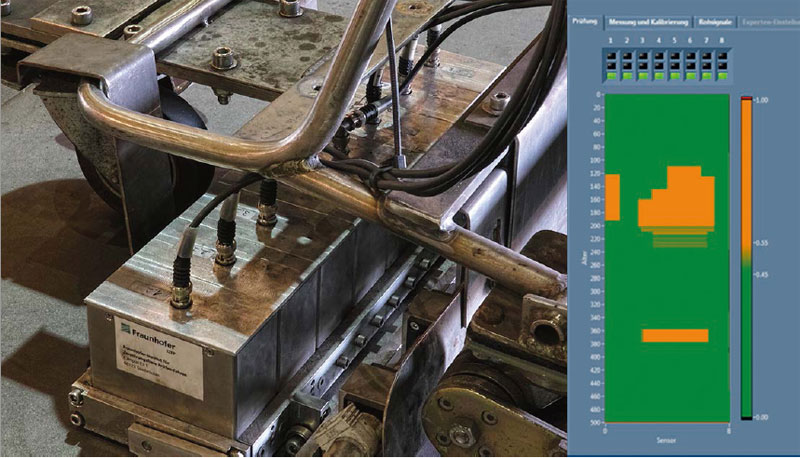

8-channel sensor carrier for sheet inspection and inspection results with colorized o.k. (green) and n.o.k. areas (orange)

8-channel sensor carrier for sheet inspection and inspection results with colorized o.k. (green) and n.o.k. areas (orange)

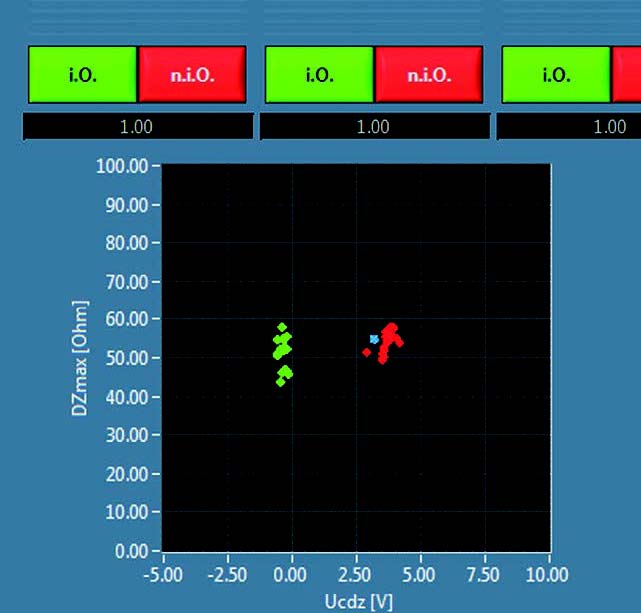

Easy calibration including visualization of o.k. and n.o.k areas

Easy calibration including visualization of o.k. and n.o.k areas

For More details, please contact LAB GAGES directly.

3MA THD Multi-Function Measuring Instrument

3MA THD Multi-Function Measuring Instrument 3MA-X8 System for Fast Materials Characterization

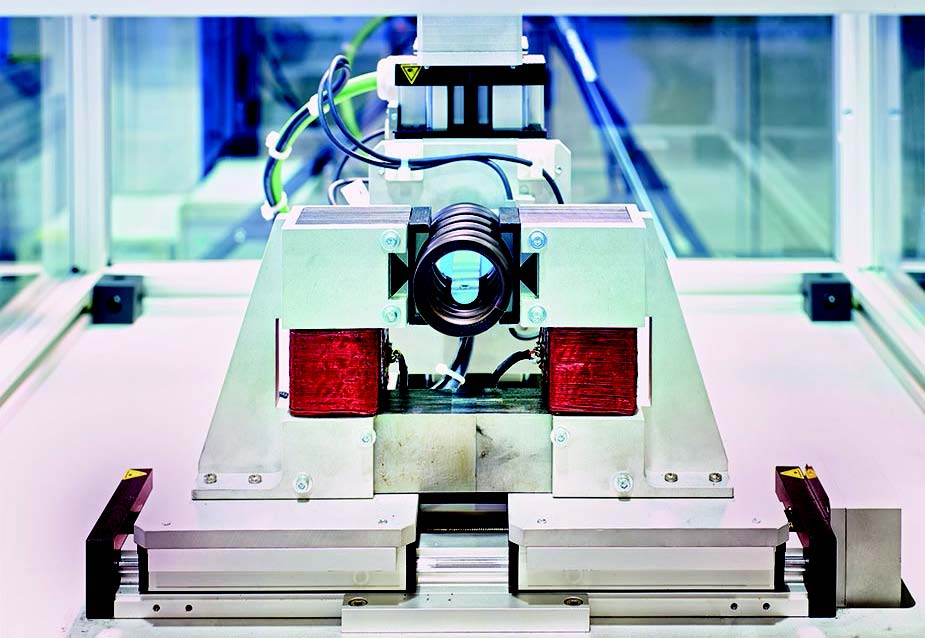

3MA-X8 System for Fast Materials Characterization Hardness & Residual Stress Depth Profiles NDE Scanner

Hardness & Residual Stress Depth Profiles NDE Scanner 3MA Inspection of Press Hardening Parts

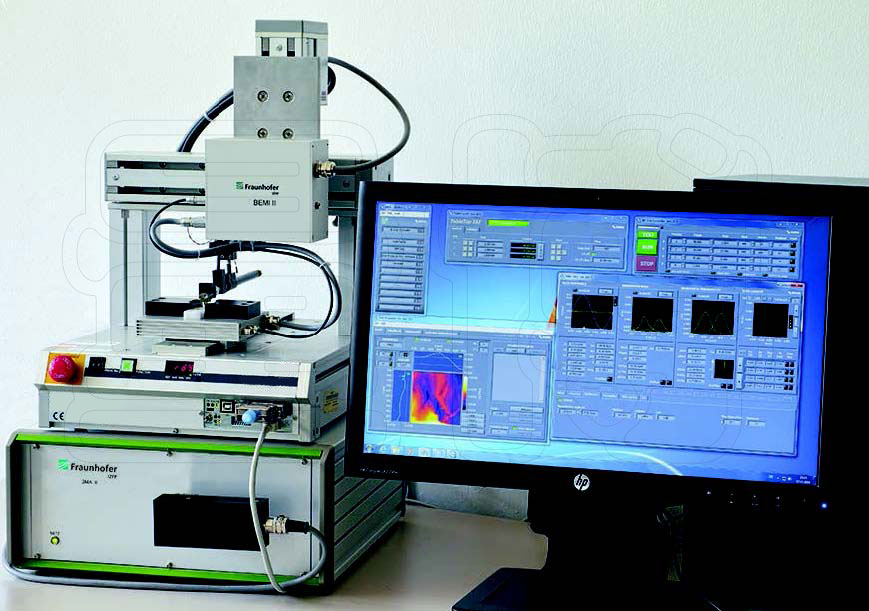

3MA Inspection of Press Hardening Parts Barkhausen Noise and Eddy Current Microscope BEMI

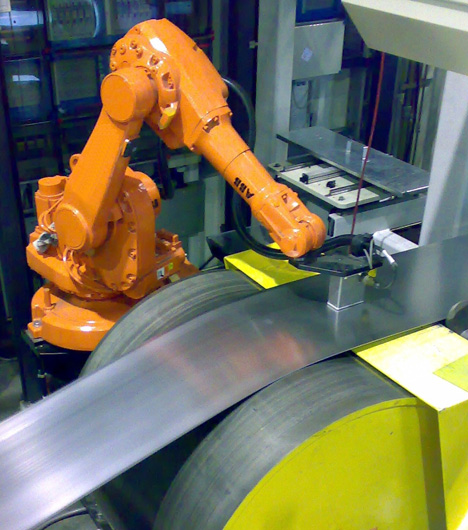

Barkhausen Noise and Eddy Current Microscope BEMI Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel

Magnus Hybrid System for In-Line Inspection of Advanced High-Strength Steel 3MA-SOM steel online monitoring system

3MA-SOM steel online monitoring system 3D SmartInspect-Intelligence in Inspection and Quality Control

3D SmartInspect-Intelligence in Inspection and Quality Control

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號

滬ICP備12021537號-1

©2012-2024 LAB GAGES

滬ICP備12021537號-1

©2012-2024 LAB GAGES