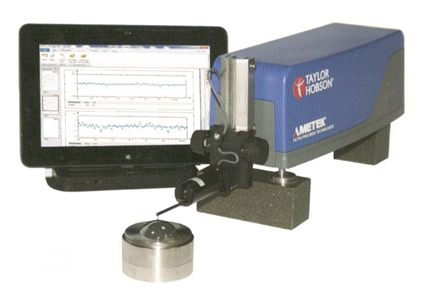

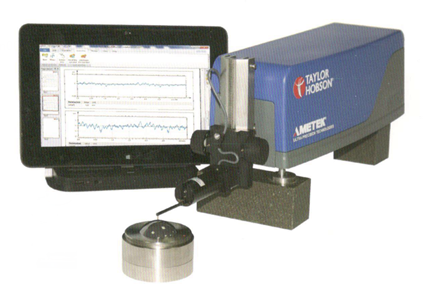

The instrument has a rugged shell. In practice, it can be maintained for a long time without maintenance. Its flexibility, reliability, and ease of use make Form Talysurf Intra a model for shop-based precision instruments in many industries. Simple roughness measurements such as Ra can be used with our Surtronic range. If you need more levels of measurement analysis and higher level measurements, Form Talysurf Intra will be a great choice for you. The instrument combines industry-recognized precision with a convenient operation that is highly practical.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li|

●1mm, 2mm and 28mm range configurations Shape (profile) and surface roughness measurements for precision metal forming and other applications. ● Horizontal drive box 50mm Suitable for most shop floor applications. This device combines accuracy and portability. ● 0.40um/50mm straightness error High-precision drive reference support measurements include waviness, shape and contour of large components. ● 0.5μm horizontal data sampling pitch Smaller components and their features can be measured more efficiently. The reduction in start length and stop length during measurement further enhances usability. ● Manual adjustment of the column For large or tall workpieces, manual adjustment of the column provides a stable, dedicated work surface for increased throughput. |

|

|

Talyprofile Software – Comprehensive Surface Roughness Analysis The Intra touch system includes all the options needed to measure surface roughness. It includes all common roughness and waviness parameters, as well as shape error analysis, removal tools, scaling tools, and full programmability for shop floor applications. ●Shape analysis Measure and evaluate radius, angle (slope) and size ●Simple user interface Combined with system programmability, it provides the right shop floor solution; it can be customized according to user requirements. ●Double contour contrast* Allows comparison with the outline of the original part. ●Contour analysis? The spatial size measurement comparison analysis allows direct comparison of design data and measurement results and results in error results. It is also suitable for large profile measurements with special hardware. ●TalyMap 3D Analysis This software has 3D shape analysis capabilities; special hardware is required. |

|

|

|

|

|

Taylor Hobson's products are very valuable ●Flexible modular system configuration saves money ●Have a unique calibration procedure to improve accuracy |

●Multitasking measurement system saves time ●Automate unattended operation and increase efficiency ●Programmed measurement program to avoid errors |

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES