|

P3123 SHD 4-Channels Hardening Depth Testing

Nondestructive Inspection of Inductively Hardened Parts and Components Using Ultrasonic Backscattering

|

Situation in surface hardening industry

Induction Hardening is a form of heat treatment in which a steel or cast iron part is heated by electromagnetic induction, immediately followed by rapid cooling (quenching). Surface hardening improves the wear resistance and fatigue strength of dynamically stressed components. These functional characteristics are mainly determined by surface hardness, hardening depth and residual stress.

Typical materials include Carbon & Alloy Steels (medium to high carbon), martensitic stainless steels, etc. An essential quality feature of the surface hardening process is the thickness of the hardened layer (SHD). Currently, the hardened layer can only be tested in random samples using destructive methods, a procedure that is both costly and time-consuming.

Fast and easy SHD control Solution

The Fraunhofer Institute for Non-Destructive Testing (IZFP) has developed an ultrasonic test instrument for fast and easy SHD control. Reduced efforts and costs for testing facilitate rapid production control for a consistently high level of quality. The test instrument is used to optimize manufacturing parameters, reduce downtimes after inductor changes, for production monitoring and quality control.

Upon quenching, the metal undergoes martensitic transformation, significantly increasing its hardness. The test method is based on the effect that the hardened layer is almost transparent to ultrasonic waves while the non-hardened material scatters them back. The backscattered signal received by a probe, is processed by the UT hardware and automatically evaluated by the software. The Surface Hardening Depth (SHD) is calculated and displayed by the software.

In most cases

the results comply with the results of destructive methods. SHD values > 1.2 mm are determined using standard equipment. Lower SHDs can be tested with special probe systems.

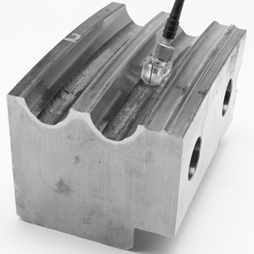

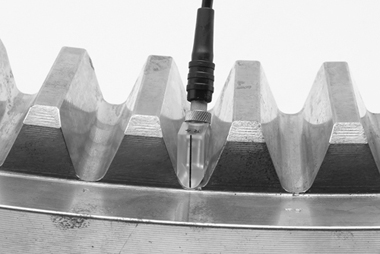

Application examples of nondestructive hardening depth testing

Advantages of P3123 SHD

? short setup times

? simple, uncomplicated calibration

? fast and easy scanning

? high test sensitivity

? comfortable sensor handling

? sensor adaptable to complex geometries

? visualization of the current test point

? testing at small radii and undercuts possible

? individual report templates

? storage of results in data base

? analysis and revaluation of test results

? line scans and circumferential scans

? automation possible

|

Features of 4-Channels Hardening Depth Testing

? 4 ultrasonic channels

? built for industrial use (IP65)

? portable for mobile use

? custom test programs

? import / export of test programs

? tools for visualization and analysis of test results

? individual test reports

|

For more details, please contact LAB GAGES directly.

Sales Manager: Mr Li

Sales Manager: Mr Li

滬ICP備12021537號-1

©2012-2024 LAB GAGES

滬ICP備12021537號-1

©2012-2024 LAB GAGES