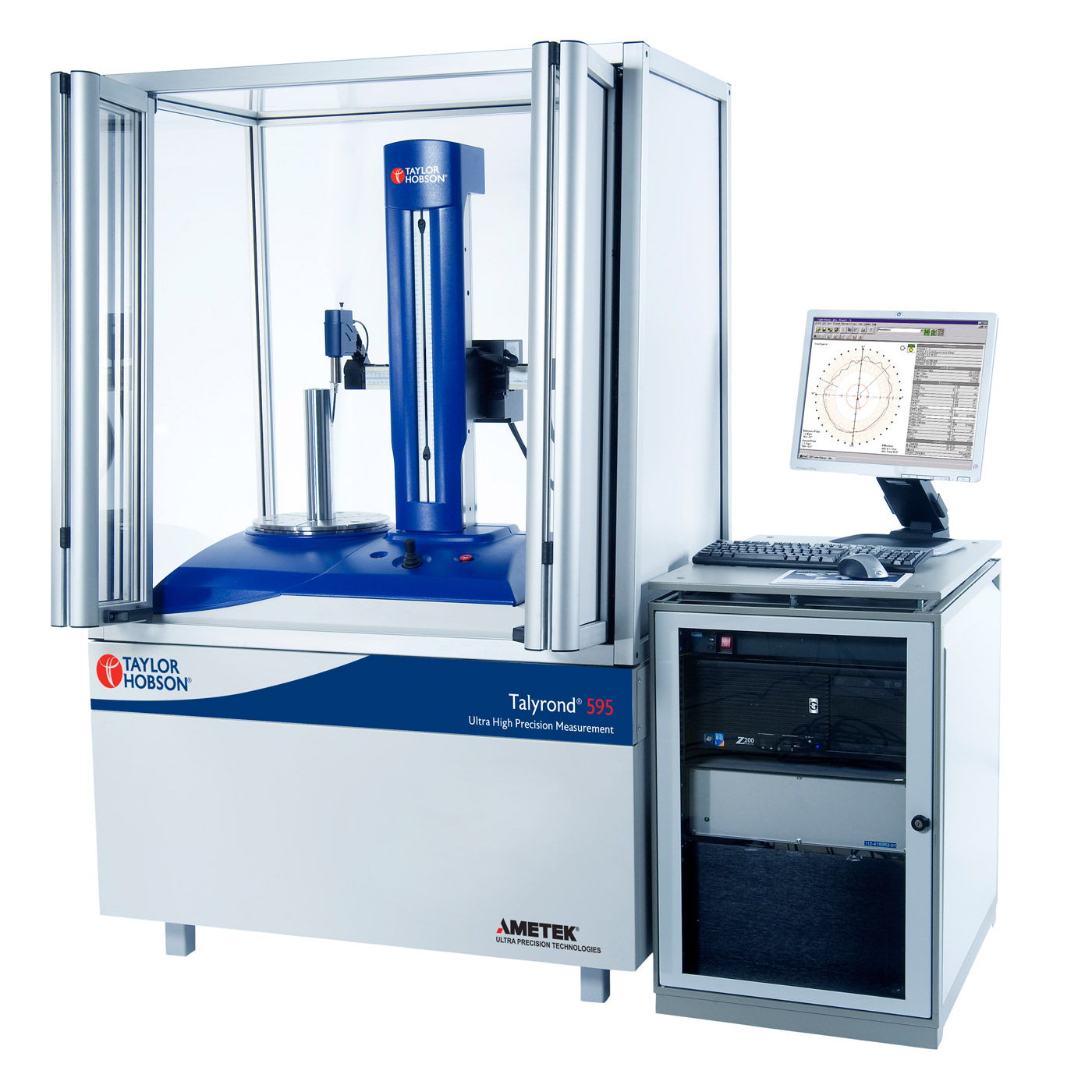

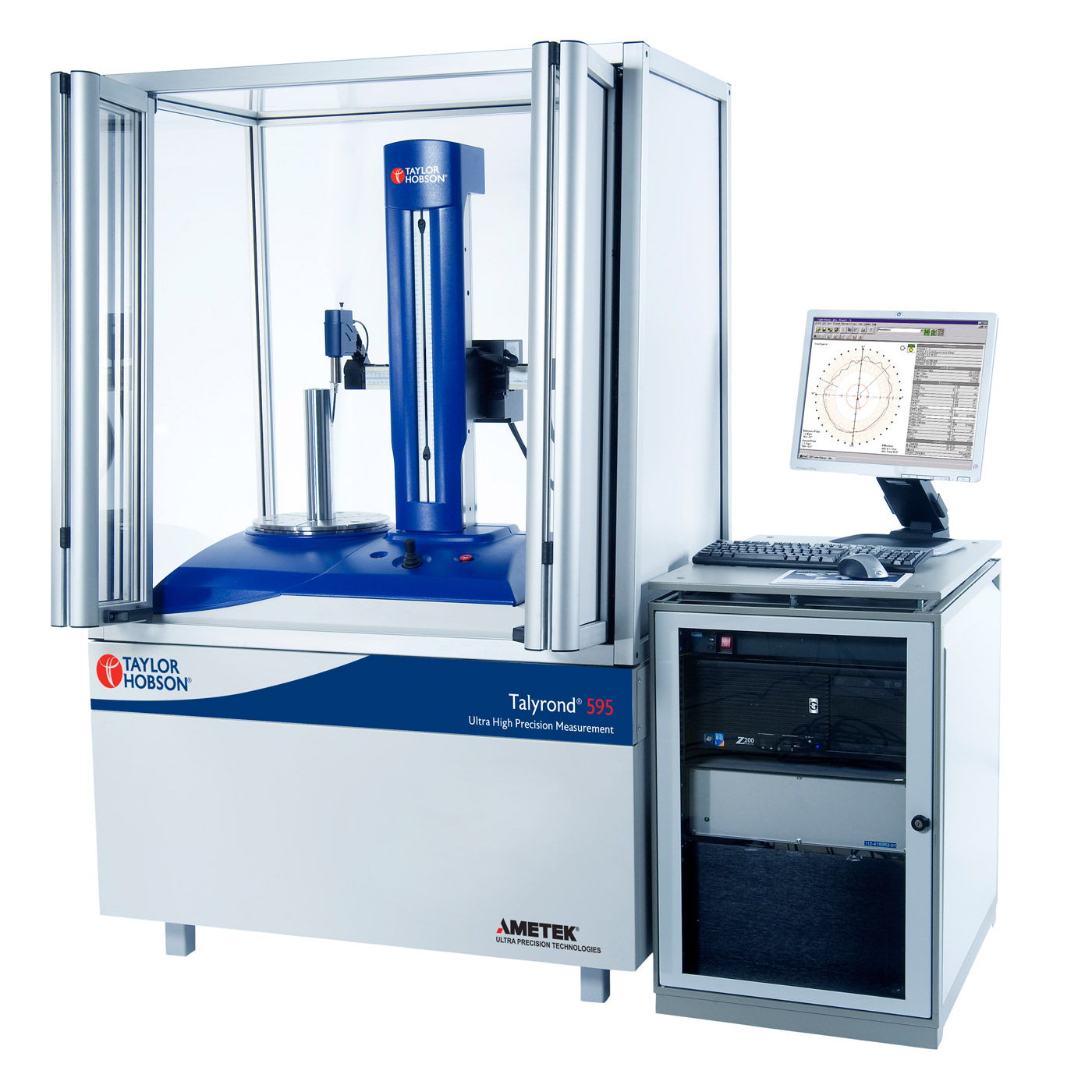

All axes of the Talyrond 595H have been precision-machined, and the software's automatic correction function has been enhanced to give the TR595H unparalleled straightness and roundness accuracy. The centering and leveling console is equipped with a high-resolution motor, which further enhances accuracy and fully automatic target setting.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr LiTalyrond 595 Revolutionary concept in the field of automated roundness detection

The system is equipped with a Talymin 5 sensor capable of measuring at the nanometer level, while the automatic cross-arm mechanism can provide unparalleled versatility to ensure that it can measure difficult to reach parts. TR595H is equipped with an active anti-vibration control bracket to ensure that the measurement environment is not affected by the external environment and ensure that the measurement environment is close to the production process.

|

High reproducibility of measurement results Decades of accumulated experience, precision machining expertise, and finite element analysis (FEA) optimization design combine to produce low-noise, near-perfect mechanical shafts. The function is further enhanced by using a traceable standard and a unique algorithm, thereby effectively eliminating the influence of the instrument on the measurement result. |

|

High-precision simulation of manufacturing processes The new Talyrond 595 roundness measuring instrument uses rotary, vertical and horizontal measuring datums to replicate the movement of the machine tool to accurately shape the shape of the workpiece. This high-precision simulation of the cutter path is a production process that you can control accurately. |

Powerful software to help you improve your processes

|

Harmonics-Determine the cause of poor workpieces Normal inspection can only detect bad parts, but the Talyrond 500 series can help you find out what causes bad products. The deviation of the shape of the workpiece can be expressed by irregularities of different frequencies and amplitudes. Harmonic analysis identifies such defects, enabling you to pinpoint problems and correct them, reducing the need to tighten tolerances in size. |

|

|

Eliminate production line bottlenecks When one or two mating parts are three-lobed or oval instead of round, assembly becomes very difficult. These low-frequency harmonics are usually caused by excessive clamping pressure on parts or unstable processing forces. Harmonic analysis after ordinary roundness measurement can help you quickly identify the cause of the fault and provide information to solve the problem. |

|

|

Fully CNC-controlled automated measurement program The Talyrond 500 has automatic calibration, automatic centering and leveling, and automatic measurement functions, which will increase your productivity, reduce measurement errors, and eliminate the need for specialized operators. Simplified “teaching / learning” programming technology combined with comprehensive user prompts and on-screen instructions make the operation of the instrument extremely easy. |

|

|

Find small problems and prevent big mistakes Noise and vibration indicate problems with alignment, balance, or flutter on the machine making the workpiece. As your level of production accuracy increases, it becomes increasingly difficult to reduce such subtle mechanical effects. The Talyrond 500 has a frictionless spindle and a high-precision spindle encoder that perfectly separate and identify high-frequency harmonics. |

|

|

Simple user interface designed for production environments ?Q-DAS data format certification ?Compatible with all ?Easy to operate ?User thread ?Traceability ?Simple tolerance ?Automatic summary report generation ?Automatic data generation |

|

|

|

|

|

Bearing raceway |

Roller bearing |

|

|

|

|

Cylinder |

Crankshaft |

|

|

|

Turbocharger |

|

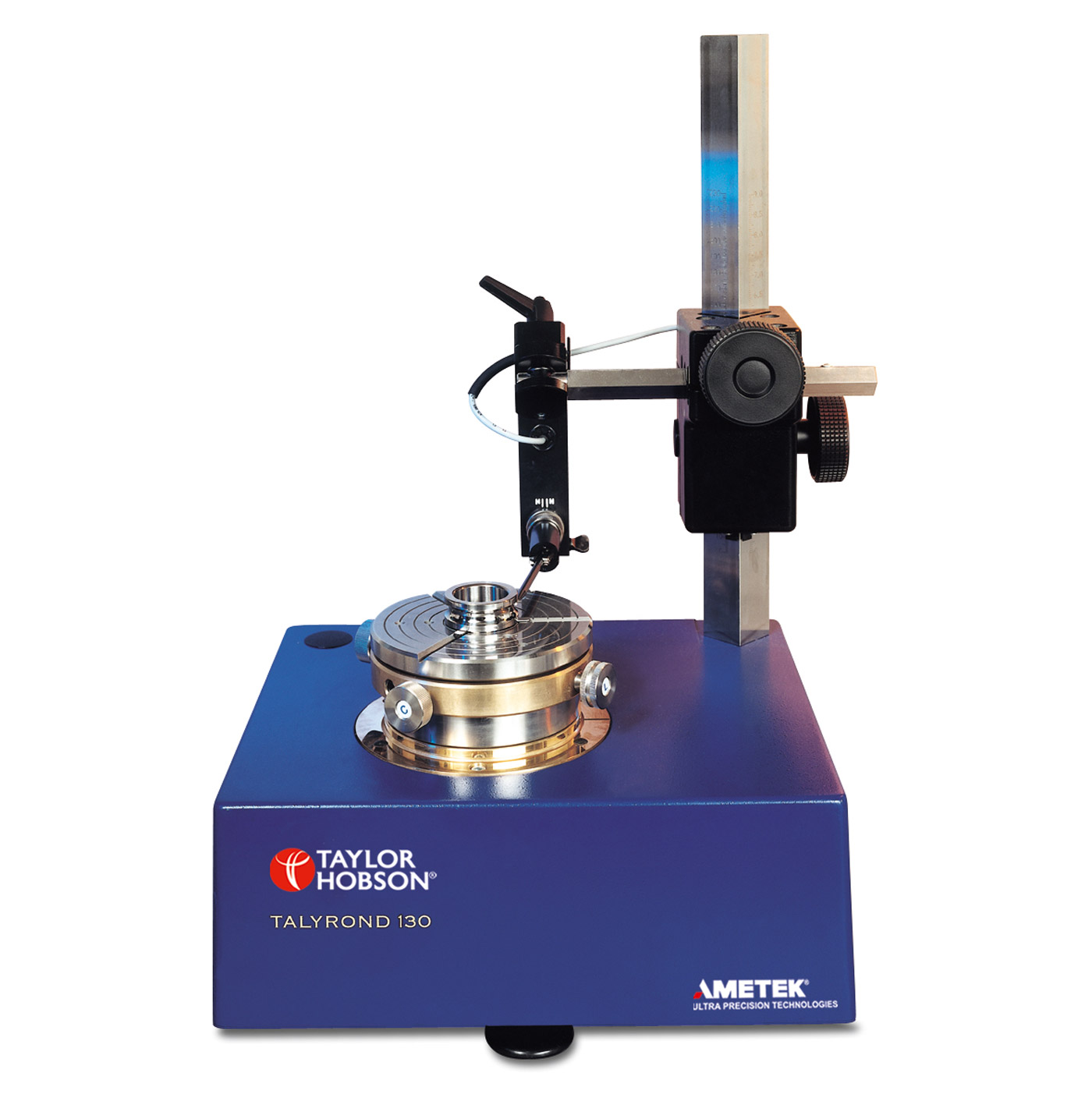

Talyrond 130 Economical High Precision Roundness Measuring Instrument

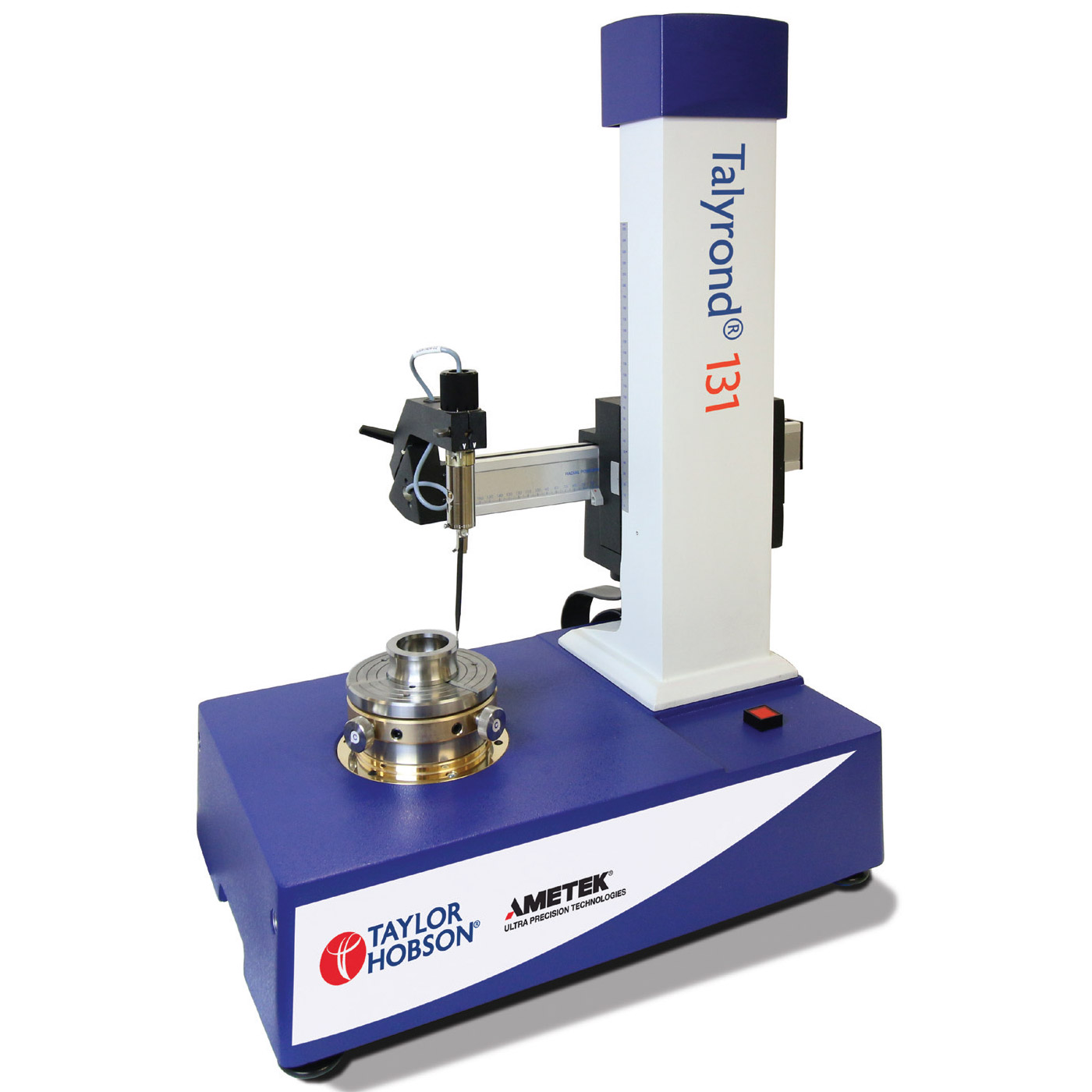

Talyrond 130 Economical High Precision Roundness Measuring Instrument Talyrond 131C Efficient Cylindricity Measuring Instrument

Talyrond 131C Efficient Cylindricity Measuring Instrument Talyrond 565 Roundness Measuring Instrument

Talyrond 565 Roundness Measuring Instrument Talyrond 585H series high precision roundness measuring instrument

Talyrond 585H series high precision roundness measuring instrument Talyrond 595 High Precision Roundness Measuring Instrument

Talyrond 595 High Precision Roundness Measuring Instrument Talyrond 400H Series Cylindrometer

Talyrond 400H Series Cylindrometer TalyMaster Multi-Part High Precision Roundness Tester

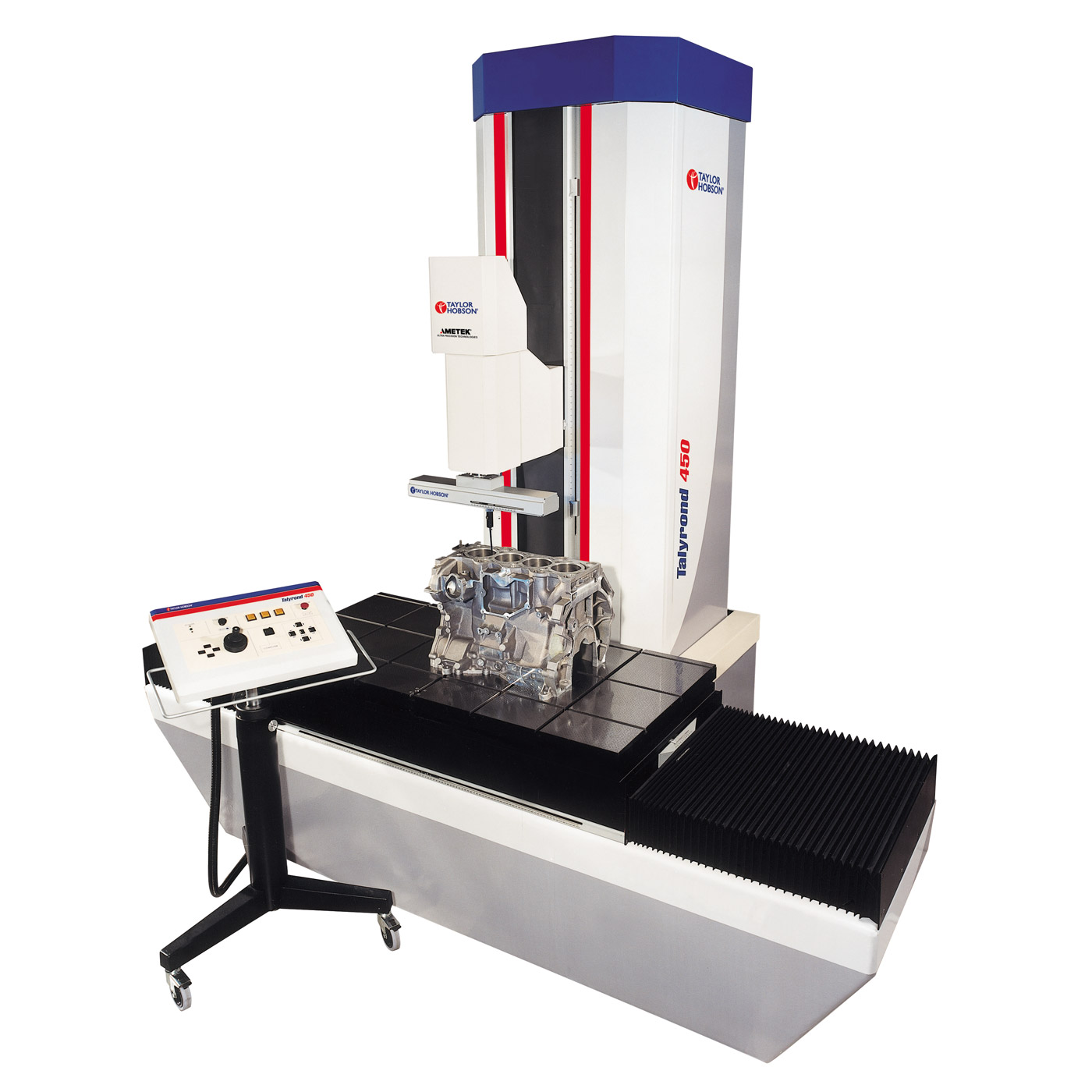

TalyMaster Multi-Part High Precision Roundness Tester Talyrond 450 Large Roundness Measuring Instrument

Talyrond 450 Large Roundness Measuring Instrument Talyrond 565-585XL large roundness measuring instrument

Talyrond 565-585XL large roundness measuring instrument Surtronic R100 Series

Surtronic R100 Series

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES