Talyrond 585H is a fully automatic roundness / cylindricity measuring instrument with unparalleled accuracy and reliability. There are 6 versions to choose from, with the right automation balance and the ability to adapt to various applications.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li|

Talyrond 585H,It is a fully automatic roundness / cylindricity measuring instrument with unparalleled accuracy and reliability. There are 6 versions to choose from, with the right automation balance and the ability to apply to various applications. Advanced electronics allow all axes to operate in high speed and precise modes for effective measurement and speed combinations of challenging components. Taylor Hopson's unique cross arm orientation provides fully automatic measurement in almost any direction, making it a universal benchmark for the instrument and round instrument industry. ■Fully automatic transverse arm longitudinal and horizontal mechanism ■Automatic sensor calibration ■Wishbone mode with automatic centering and leveling ■High-precision air bearing spindle accuracy +/- 0.015 um ■Sensor resolution 0.3 nm ■300 mm, 500 mm, 1000 mm, or 1200 mm vertical post axis |

|

|

|

|

|

Talyrond 500LT series, new concept of roundness measurement |

|

|

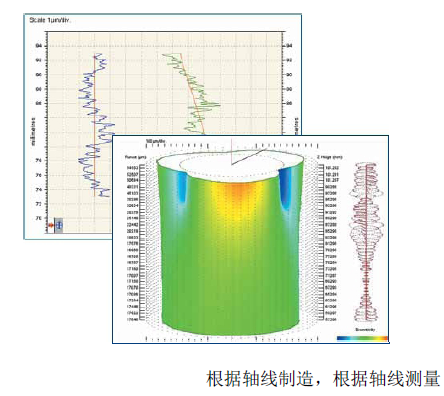

High-precision simulation of manufacturing processes The new Talyrond 500 roundness measuring instrument uses rotary, vertical and horizontal measuring datums to replicate the movement of the machine tool to shape the shape of the workpiece accurately. This high-precision simulation of the cutter path gives you precise control over the production process. |

High reproducibility of measurement results Decades of experience, precision machining expertise and finite element analysis (FEA) optimization design combine to produce low-noise, nearly perfect mechanical shafts. The function is further enhanced by using a traceable standard and a unique algorithm, thereby effectively eliminating the influence of the instrument on the measurement result. |

|

Multidisciplinary measurement Understanding the manufacturing process means understanding the measurement process Manufactured according to the axis, the spindle of the machine tool is used to restrict the workpiece to rotate around a fixed axis according to the axis measurement, and the tool moves on a guide rail that is parallel or perpendicular to the axis. Only in this way can the produced parts naturally form a column or a circle and have a functional axis. Based on the same principle, the Talyrond 500 measures a cylindrical or circular surface with a probe along the same axis of rotation, profile, and then adjust the machine path to control the process and improve product quality. |

|

|

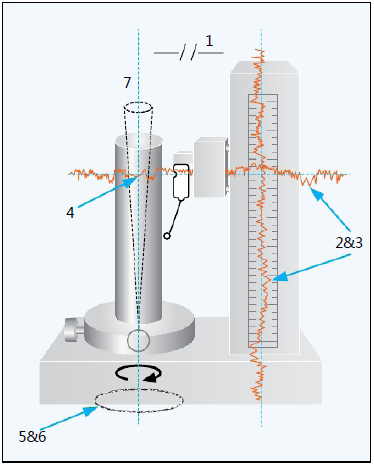

Comprehensive professional metrology design Construction of the 500 Series is key to measuring integrity |

|

|

Reshape parts Taylor Hobson's core competitiveness lies in cylindrical grinding, surface grinding and diamond turning. All these disciplines are combined with knowledge of drive mechanisms to form instruments with low noise and high geometric accuracy to ensure the reshaping of components |

|

|

Frictionless air bearing spindle The instrument's spindle, like any spindle-based machine, is important in ensuring measurement integrity. With Taylor Hobson's own diamond lathes, we are able to establish a benchmark with first-class accuracy and reliability. |

|

|

Instrument base Using finite element analysis software, the cast iron base provides a solid foundation for high-precision air-bearing spindles and vertical straightness datums, ensuring movement and weight do not affect measurement results. For testing laboratories or production environments, we also offer a range of passive or active vibration isolation devices. |

|

|

Straightness benchmark Using traceable standards and technologies developed by Taylor Hobson, vertical columns with perfect straightness, waviness and roughness are processed to exacting standards. The straightness benchmark has been further improved to ensure that the replasticity of the component is guaranteed to be low or unaffected by the instrument |

|

Accessories

|

1. Environmental isolation cover and active vibration isolation device |

2.Talyrond Standard Calibration Ball |

||

|

|

||

|

3.Six-jaw chuck |

|||

|

|||

|

4.Standard styli |

5.Precision Collet Chuck |

6.High-precision glass hemisphere |

|

|

|

|

|

|

7.High-precision standard cylinder |

8.Centering attachment |

9.Calibration block |

10.Calibration kit |

|

|

|

|

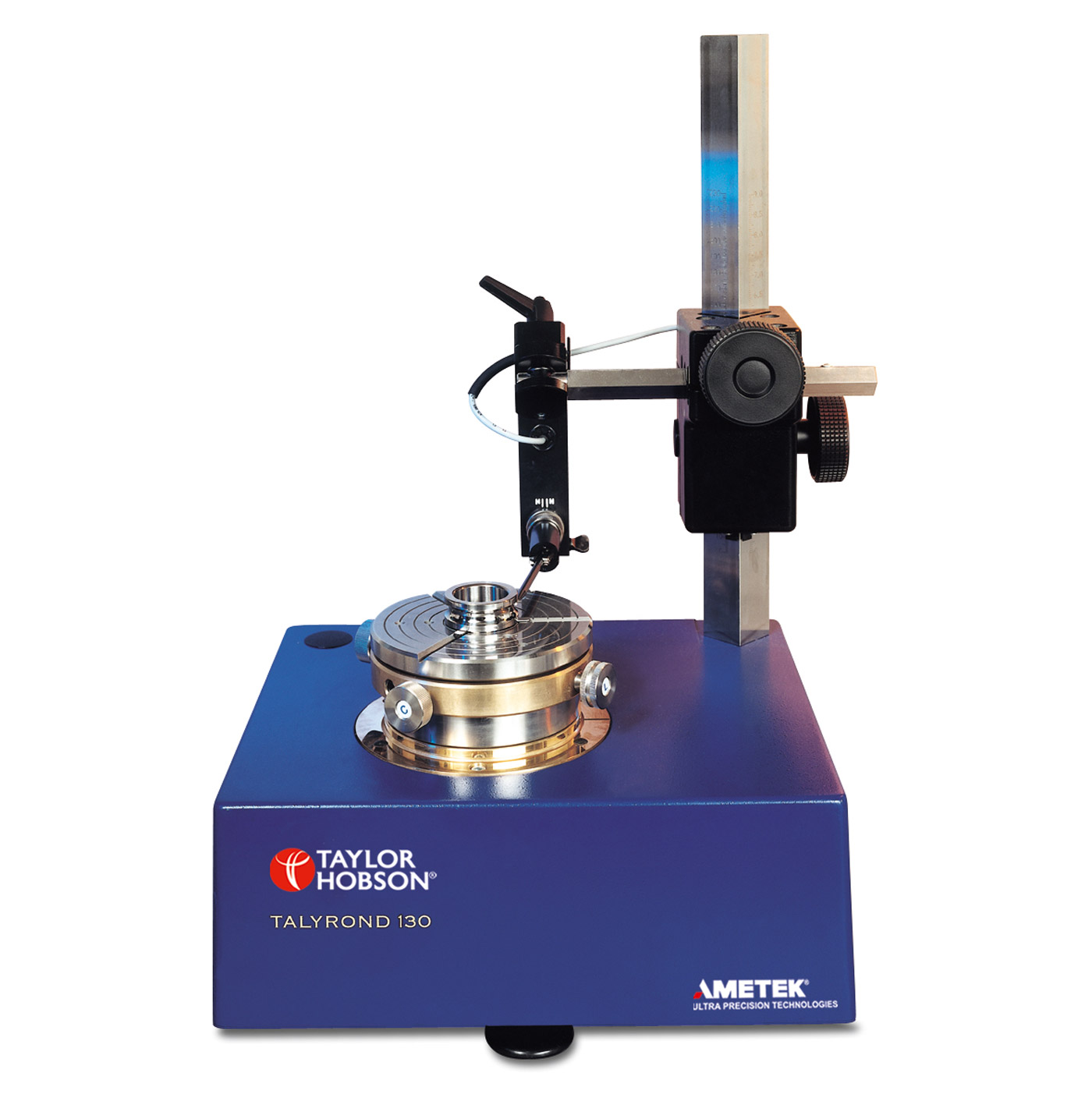

Talyrond 130 Economical High Precision Roundness Measuring Instrument

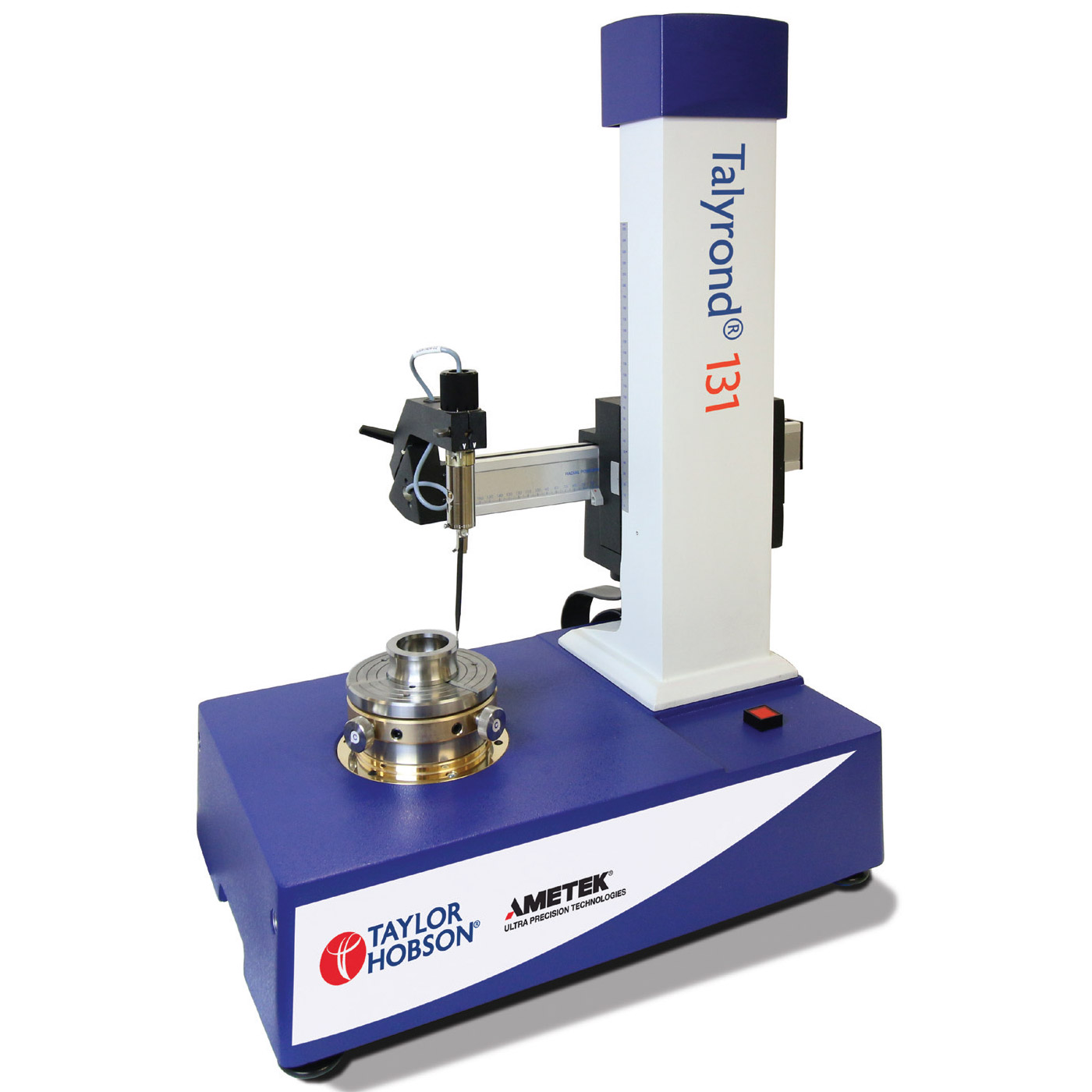

Talyrond 130 Economical High Precision Roundness Measuring Instrument Talyrond 131C Efficient Cylindricity Measuring Instrument

Talyrond 131C Efficient Cylindricity Measuring Instrument Talyrond 565 Roundness Measuring Instrument

Talyrond 565 Roundness Measuring Instrument Talyrond 585H series high precision roundness measuring instrument

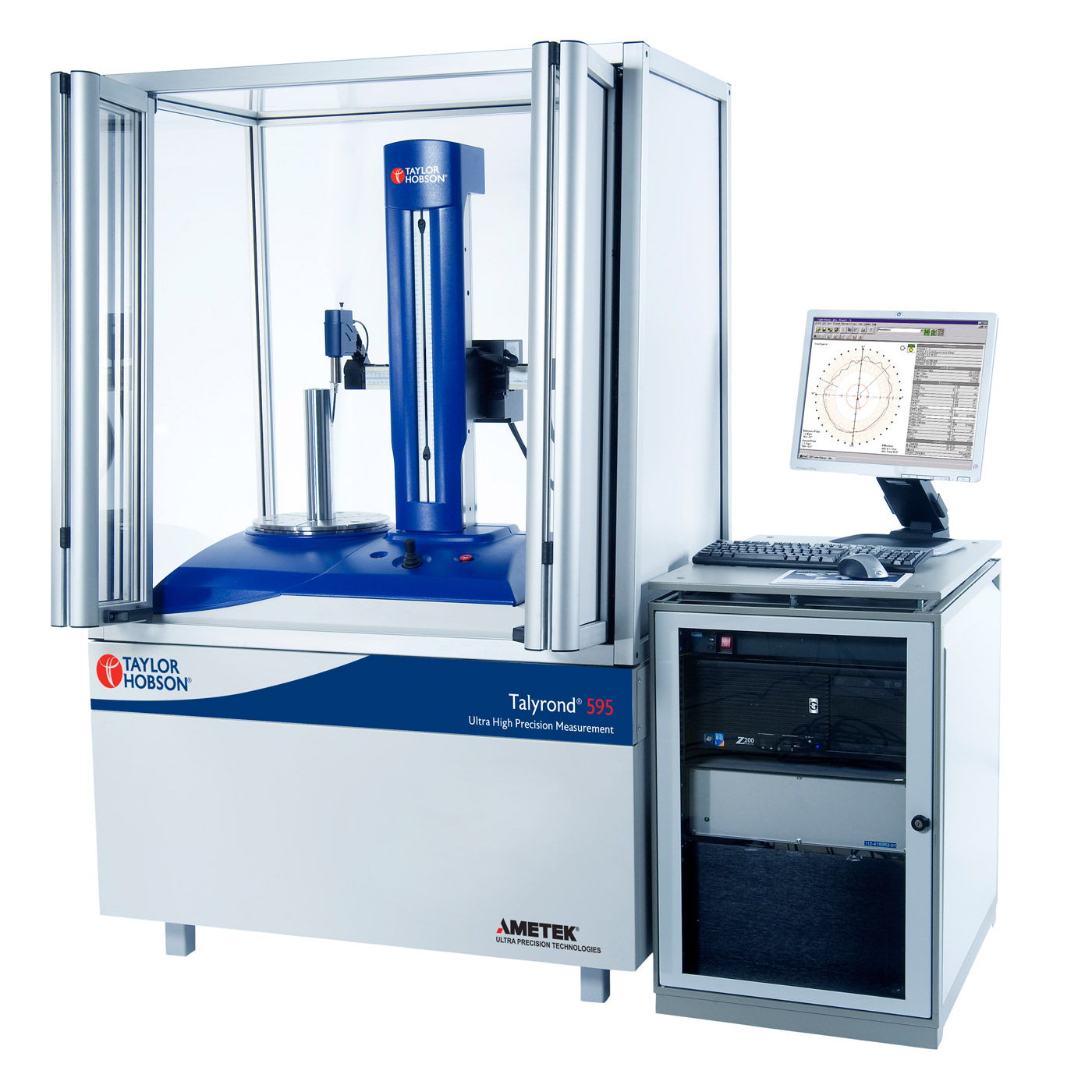

Talyrond 585H series high precision roundness measuring instrument Talyrond 595 High Precision Roundness Measuring Instrument

Talyrond 595 High Precision Roundness Measuring Instrument Talyrond 400H Series Cylindrometer

Talyrond 400H Series Cylindrometer TalyMaster Multi-Part High Precision Roundness Tester

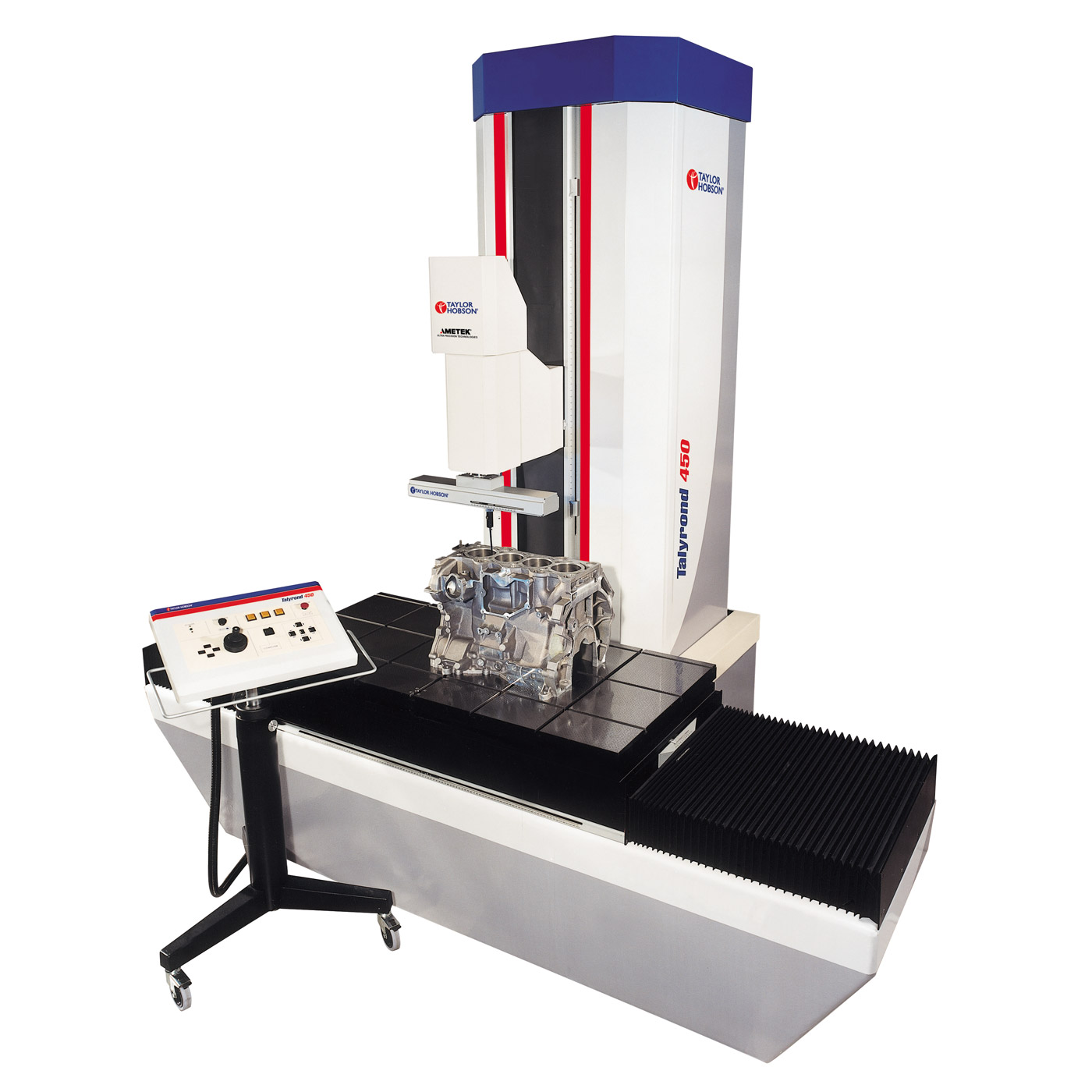

TalyMaster Multi-Part High Precision Roundness Tester Talyrond 450 Large Roundness Measuring Instrument

Talyrond 450 Large Roundness Measuring Instrument Talyrond 565-585XL large roundness measuring instrument

Talyrond 565-585XL large roundness measuring instrument Surtronic R100 Series

Surtronic R100 Series

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號

滬ICP備12021537號-1

©2012-2024 LAB GAGES

滬ICP備12021537號-1

©2012-2024 LAB GAGES