Leave a Message Mechanical characteristics of Anti-wear protection and functional coatings

Anti-wear protection and functional coating

In the automotive field, DLC coatings and surfaces made of NiP or other hard materials are increasingly used. They are effective, for example, to protect engine components from wear. FISCHER provides high-performance measuring equipment to help you achieve quality control of functional coatings, allowing you to accurately measure surface hardness and other mechanical properties.

Mechanical characteristics of Anodized Coating

In the automotive industry weight reduction – and the associated fuel savings – are top priority, which is why lightweight materials such as aluminum are used. In order to withstand mechanical stresses, however, these softer components must be made wear resistant. For this reason, hardcoat (Type III) anodization is becoming ever more common.

While hard anodized coatings are typically 30-80 μm thick, some are only a few μm! For these coatings, conventional hardness measurement systems that rely on optical evaluation of the indentation (e.g. Vickers method) approach the limits of their ability. A much better suited method is the instrumented indentation test, which can be applied to measure not only the hardness in terms of plastic deformation (HV), but also to assess other quality-determining characteristics. Using the instrumented indentation test, even very thin anodized coatings can be analyzed without risking influence from the substrate.

For such technical applications hard anodized coatings must have a consistent hardness of 400-600 HV across the entire section. Soft anodized coatings for decorative applications have a hardness of about 200-400 HV, which is reached a few hundred nm below the surface.

NDT Mechanical characteristics Technology of Coatings

FISCHERSCOPE Nanoindentation and mechanical properties testing instrument

The FISCHERSCOPE HM2000 with its ESP (Enhanced Stiffness Procedure) mode is able to determine mechanical properties like the Vickers hardness or the elastic indentation modulus dependent upon the depth.

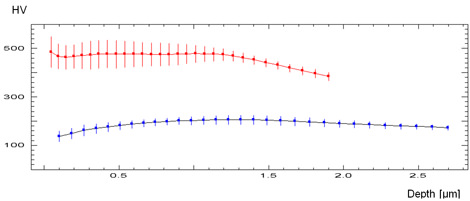

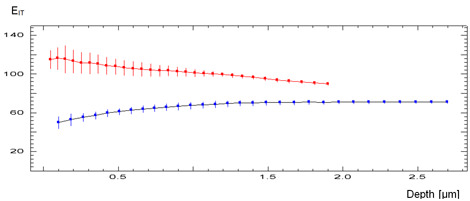

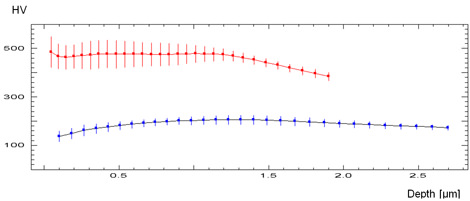

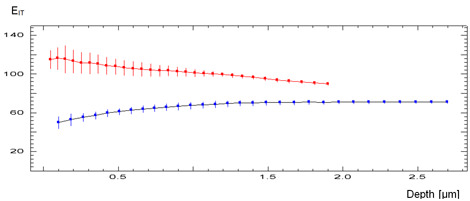

Figure 1a/b shows the Vickers Hardness HV (calculated from the indentation hardness HIT) and the indentation modulus EIT of two coatings: a hard anodized coating (480 HV) of 11 μm thickness (shown in red) and a soft anodized coating of 14 μm thickness (shown in blue). The higher standard deviation for the hard anodized coating stems from the roughness of its surface.

Fig.1a: derived data for Vickers hardness (HV) of a hard anodized (red) and a soft anodized (blue) coating

Fig.1b: indentation modulus (EIT) of hard anodized (red) and a soft anodized (blue) coating

In Figure 1a one clearly sees the consistent hardness of the hard anodized coating and the increasing hardness of the softer anodized coating, which also exhibits less elasticity (Figure 1b, indentation modulus). On the hard anodized coating, the elasticity decreases as one approaches the substrate.

The FISCHERSCOPE HM2000 is optimally suited for the precise determination of the mechanical characteristics of thin anodized coatings. Beside the hardness, other parameters such as the plastic or elastic material characteristics can be accurately assessed. Please contact LAB GAGES for further information.

FISCHERSCOPE Nanoindentation and mechanical properties testing instrument

FISCHERSCOPE Nanoindentation and mechanical properties testing instrument

Fig.1a: derived data for Vickers hardness (HV) of a hard anodized (red) and a soft anodized (blue) coating

Fig.1a: derived data for Vickers hardness (HV) of a hard anodized (red) and a soft anodized (blue) coating Fig.1b: indentation modulus (EIT) of hard anodized (red) and a soft anodized (blue) coating

Fig.1b: indentation modulus (EIT) of hard anodized (red) and a soft anodized (blue) coating

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES