Surface heat treatments and machining processes are necessary to provide materials with the desired strength, shape, and surface quality. Hardening the material’s surface by case-hardening, induction hardening, or nitriding will increase the resistance to surface wear without impairing the material’s toughness in the bulk. Usually, the workpiece is already formed or milled to its final shape when surface hardening is applied. Therefore, unavoidable quenching distortions that are due to hardening usually have to be removed afterwards. In order to ensure a high-dimensional workpiece of accurate form, a subsequent fine machining of the workpiece’s surface by means of turning, grinding, honing, or polishing is often required after hardening. However, this surface machining process can, again, result in unwanted changes in the material’s microstructure.

From left to right, three important surface hardening methods: surface carburizing hardening, nitriding, and induction hardening.

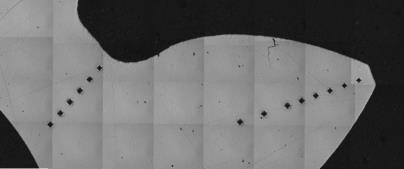

The most important quality characteristics of surface-hardened workpieces are the hardening depths, i.e., the surface-hardening depth (SHD) after induction hardening, the case-hardening depth (CHD) after carburizing, the nitriding hardness depth (NHD) after nitriding, and the fusion hardness depth (FHD), e.g., after laser hardening. In addition, the hardness and residual stress values at the surface and in the bulk or even the depth-profiles of hardness and residual stress are relevant in order to assure the quality of such workpieces.

|

|

Example of routine laboratory destructive CHD measurement with hardness gradient evaluation curve

However, today's industrial production is highly automated, which is why it is also necessary to automate quality inspections. The quality characteristics of raw materials, semi-finished products and end products should not only be determined in the materials laboratory, but also parallel to or embedded in production. Key material properties should be continuously and completely documented to monitor and even control the manufacturing process to optimize them in terms of quality, efficiency and cost. These goals can only be achieved by applying appropriate non-destructive testing (NDT) methods.

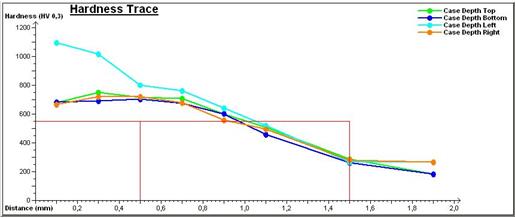

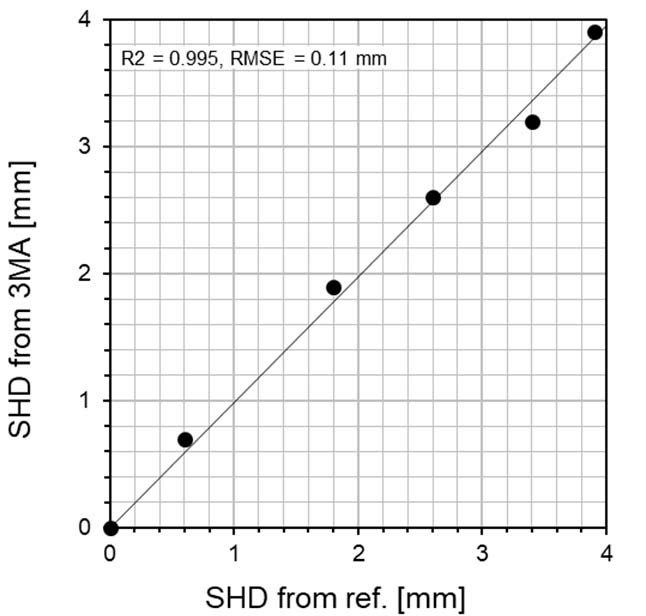

All of these material parameters can be determined with 3MA technique after appropriate calibration. Figure below shows the CHD and SHD calibration results. For all surface-hardening mechanisms, 3MA not only allows the hardening depth to be determined, but also the hardness at the surface, the core hardness, and the hardness values between. 3MA technique is a well-ordered combination of four micromagnetic methods: Barkhausen noise (BN), harmonic analysis of tangential magnetic field strength (HA), multi-frequency eddy current analysis (EC), and incremental permeability (IP).

|

|

Results of the calibration to hardening depth: (a) case‐hardening depth (CHD) and (b) surface‐hardening depth (SHD).

With verification measurements on parts not used in these calibrations, the RMSE values, i.e., the average deviations between the nondestructive and destructive measuring data of 0.07 mm for CHD and 0.13 mm for SHD could be determined. Applications for the determination of FHD with 3MA have also been previously described. Especially impressive are the results of 3MA for determining the NHD, e.g., in piston rings [44]. The typical values of NHD were between 60 and 100 um. It was found that, for the NHD values determined with 3MA, the reproducibility is better than for the values determined by metallographic investigations (Nht700 test).

|

|

|

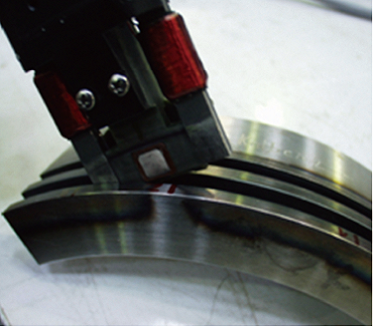

Example parts for 3MA non-destructive testing of quality of surface heat treatment [CHD / NHD / SHD / FHD / hardness]

Meanwhile, the application of NDT in production has become an indispensable part of modern industry and characterizing materials in terms of microstructure, condition, and properties are important tasks for today’s techniques of production-integrated NDT. In this context, the "3MA micromagnetic" methods are probably the most prominent representatives of such techniques. 3MA Micromagnetic methods allow for the nondestructive characterization of all ferromagnetic materials, showing magnetic interactions with the microstructure and stresses on a microscopic level.

The method combination is crucial in achieving correct and reliable results in the application of micromagnetic methods. Without this approach, the 3MA technique would not be so accepted in this dimension in research and industry. For more information, please contact LAB GAGES, or go on to visit our 3MA series Nondestructive Testing Systems Product Center.

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES