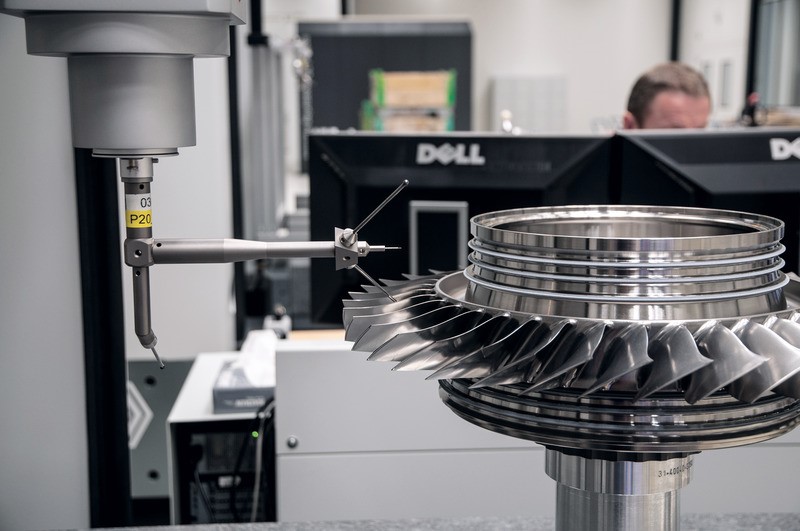

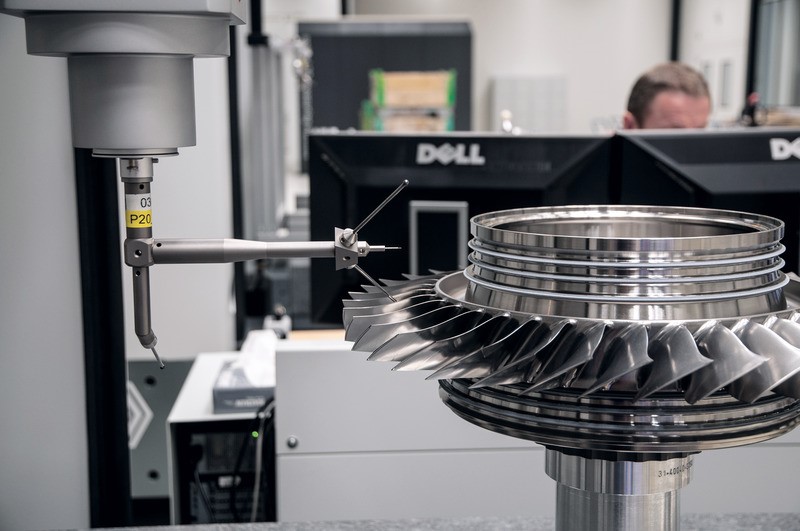

Leave a Message High-precision measuring machine applying in German engine companies

MTU Aeros Engines' metrology team uses standard clamping systems to hold various types of leaf discs and measure them in production and perform subsequent inspections.

MTU Aero Engines is a company that develops, manufactures, sells and maintains civil aircraft, military aircraft, helicopter engines and industrial gas turbines. A successful product in the MTU portfolio is the geared turbofan jet engine, a joint venture with American Airlines Pratty & Whitney.

MTU is responsible for the first four stages of the high pressure compressor - the disc structure, which improves the performance of the fast rotating low pressure turbine. From a production technology point of view, the leaf disc is a complex component in which the vanes and the disc are integrated into one component. So they need a metering technique for efficient inspection of the leaf disc components. In the process of finding a measurement partner, shorter measurement times, less measurement instability, stable production processes, and good test instrument capabilities are the primary selection criteria. Finally, Hexagon Manufacturing Intelligence PTS won.

Hexagon Manufacturing Intelligence PTS recommends the high-precision Leitz PMM-C coordinate measuring machine with integrated turntable, flexible QUINDOS measurement software and the option to use the I++ Simulator for offline programming.

With this advanced measurement system, the measurement time specified by MTU is significantly shortened. When measuring the sample, Hexagon Manufacturing Intelligence PTS reduced the overall measurement time by 65% while maintaining the performance of the test process. The measurement time for the blade profile is even reduced by up to 75%.

滬ICP備12021537號-1

©2012-2024 LAB GAGES

滬ICP備12021537號-1

©2012-2024 LAB GAGES