DuraScan is based on a compact and asymmetric design based on the obtained V-shaped concept, using a motorized probe and a fixed stage in the vertical direction. The probe is movable in the y-axis and z-axis directions, while the stage is movable in the x-axis direction.

Inquiry Online Sales Manager: Mr Li

Sales Manager: Mr Li

|

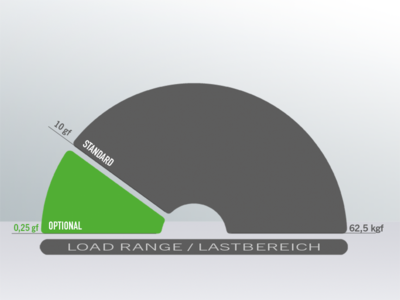

High accuracy and wide application range DuraScan G5 has a groundbreaking standard load range of 10g to 62.5kg, greatly expanding the application range of the hardness tester. The load range can also be optionally extended to 0.25 g to 62.5 kg and can be added at any time! At the same time, a series of electronic load cells are used to continuously and accurately monitor the test force. G5-the fifth generation electronic load hardness tester. |

|

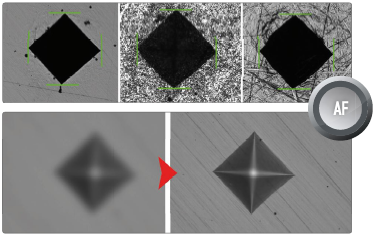

Innovative image evaluation system The 10-megapixel camera used in all products of the DuraScan G5 series sets a new benchmark for image quality in hardness testers. The intelligent utilization of the high-resolution camera chip realizes the 3x zoom function. With this innovative solution, the use of objective lenses is optimized, which further expands its range of applications. The fully-automatic evaluation system that has been tested in practice can adjust the screen brightness very reliably and automatically evaluate the indentation. |

|

Speed up the testing process The DuraScan G5 series' innovative solutions help reduce test time. A new, protected height-adjustment device enables the measuring unit to move up and down quickly at 10 times the speed. This saves valuable time when changing specimens with different heights. All DuraScan G5 series devices are equipped with xCHANGE interface as standard, which can easily import and export test parameters and test results automatically, which greatly improves data transmission speed. |

|

Intuitive software with calibration assistance The ecos Work-flow measurement software independently developed by EMCO-TEST with Calibration Information System (CIS) can provide efficient and intelligent solutions for all traditional tasks of hardness testing. With the help of the software, users will step through the entire process from measurement to data backup. Intuitive operation interface makes operation simple, convenient and reliable A special feature of ecos Workflow CIS is that it has an integrated calibration assist function that monitors all calibration methods and makes the normative inspection of the hardness tester very easy. This auxiliary function guides the operator to perform tests in accordance with ISO and ASTM standards, completes the entire test process and ensures that records meet the standard requirements. |

|

Provide appropriate equipment workers to meet any requirements Load range from 0.25g to 62.5g |

|

|

ecos Workflow CIS enables advanced data management Process data simply and securely |

|

|

|

|

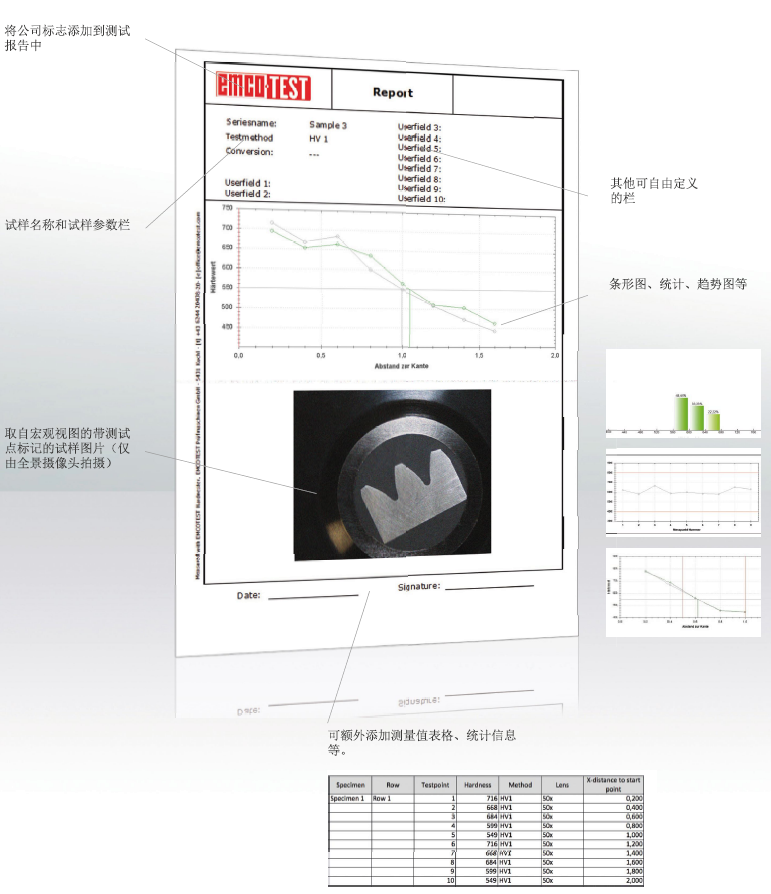

Efficient data management system To ensure continuous recording and reliable classification of workpiece measurements, all DuraScan G5 models provide multiple methods of data output and backup. In addition to backing up the test results directly on the hardness tester, all data collected during the test can also be saved as .pdf. .Xls (Excel) or .xml format files. At the same time, the output in XML file format can also be achieved with Q -Connection of DAS system. The integrated export editor provides several adjustment options. In addition to exporting the scope and order of the measurement data, a new file can also be automatically generated after each measurement, making further automated processing of the data more convenient. |

|

|

ecos Workflow xCHANGE The xChange interface is standard on all DuraScan GS and DuraVision series hardness testers. This interface can meet all customer requirements for the connection between the hardness tester and the database and data input equipment, as well as for fully automatic or unmanned operation. ecosWorkfIowxChange is based on the commonly used XML format, so it has the advantages of easy to use and clear structure. |

Generate separate test reports All models are equipped with a direct print function as standard. With the help of this function, a test report can be generated from the connected printer. Models DuraScan 70 G5 and 80 G5 can integrate a sample picture generated by a panoramic camera (see example below). In addition, the report of the test results can be easily drafted through a flexible format generator. |

311,Building 5,No.81,Meiyue Road,Waigaoqiao Free Trade Zone,Pudong,Shanghai,China

amy@labgages.com

021-50473900

About LAB | Cooperative Brand | Contact us | Sitemap

滬公網(wǎng)安備 31011502000213號(hào)

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES

滬ICP備12021537號(hào)-1

©2012-2024 LAB GAGES